Believe it or not … there is a RIGHT and WRONG way to turn the power on and off to your CNC equipment at the start and end of the day. And the difference can mean increased life for a lot of the electrical components at the heart of your equipment.

During my 20+ years as a field service engineer for Mori Seiki and Yamazen USA … the first thing I taught clients when they received their new CNC machine was the correct way to power up and power off. I knew from my experience that even this little lesson would bring big dividends over the long haul.

The main idea is to dissipate power or bring power on line in an orderly and limited manner. Big power boosts or cuts can damage delicate electrical components over the long haul and can even mean damage in the short run that will eventually lead to big failure.

Let’s start with the power OFF routine …

We’ll start with the power OFF because power on is the exact opposite. So we want to get this done right first off.

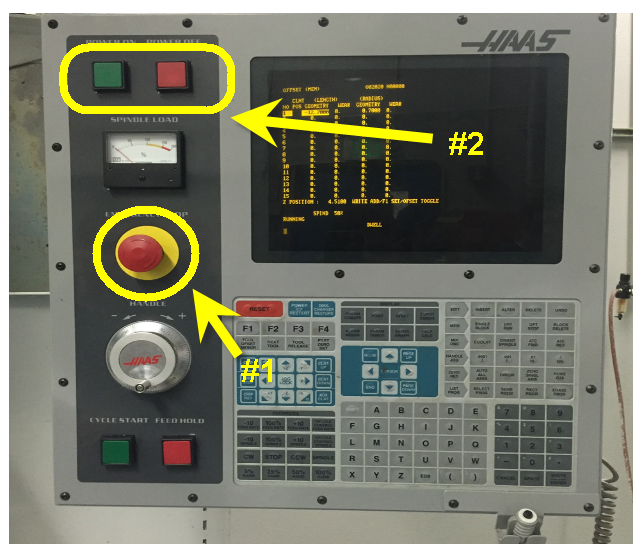

The WORST thing to do is to simply cut the power using the breaker on the machine. This creates a huge power vacuum all at once … not a good thing for delicate CNC electrical components. That breaker or switch usually look something like this …

At POWER OFF … my recommended process is :

- Hit the big RED button … E-STOP is #1. This will kill the power to the motors and lock the axis movement preventing any axis jumps due to a bigger power cut. The E-STOP circuit is designed specifically for this type of power cut.

- #2 — CONTROL POWER OFF. Next up press the power off button for the CNC control. This will now kill the power to the CNC control components and control panel in an orderly manner. Again … that’s what the control off circuit is designed for.

- LAST — turn off the circuit breaker on the machine. Not the panel on the power box at the wall of the shop … the one at the machine. This will be the final power kill but at this point on limited items are still powered up and running.

(2) Power Off

(3) Main Breaker

This is an orderly process that will turn the power off and dissipate power from the components in an orderly and minimum manner.

POWER ON … the exact opposite :

- MAIN BREAKER ON

- CONTROL POWER ON

- UNLOCK the E-STOP (which was depressed at power off) … once that is unlocked the power will automatically return … although on some circuits you may need to press the CONTROL POWER ON again once the E-STOP is released.

Should I Even Bother To Power Off My Machine ?

I know a lot users don’t even bother to turn the machine off … they just keep it powered on continuously. I also know a lot of thinking here is that the power surge to the components is worse. Yes … that’s true if you just kill the BREAKER as your power off routine … but if you use the process I outlined here you will not adversely effect your electronics with power off … and you’ll save a TON on your electricity bill !!

Hope you found this article useful …

Happy LONG and PROSPEROUS Chipmaking !!

Kenney Skonieczny – President

Kentech Inc.