Tips and Tricks ... from the Real World for the REAL WORLD

The CNC Machinist Blog

From Kentech Inc. … the Creators of Kipware®

Using our 35+ years of machining, CNC machine service and machine shop management experiences, Kentech Inc. offers TIPS and TRICKS for all things metalworking … machine maintenance … CNC programming … all learnt and gathered from the REAL WORLD. Please explore our BLOG and hopefully take away a tip or trick in the process. ENJOY !!

The GREAT DEBATE ...

Cutter Comp or not !!

Explore thoughts and comments from our CNC programmers / software developers on why using cutter compensation in your CNC programs is the SMART CHOICE !!

Real World TipS from kentech inc.

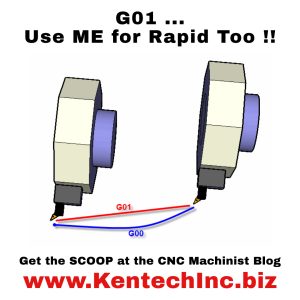

G01 ... Use ME for RAPID TOO !!

Explore all the REASONS … all the WHY’s … and all the HOW’S … G01 may be a better alternative for RAPID moves.

Be sure to check out the end of the article for an AUTOMATED solution to easily convert ANY G code program from G00 to G01.

Some of Our Most Popular Posts

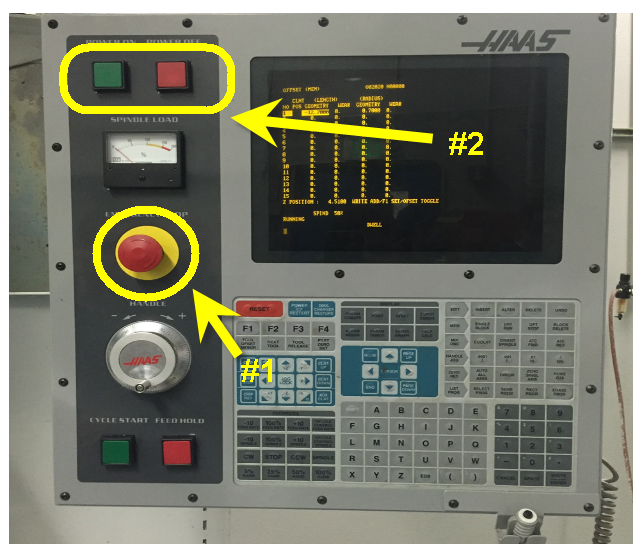

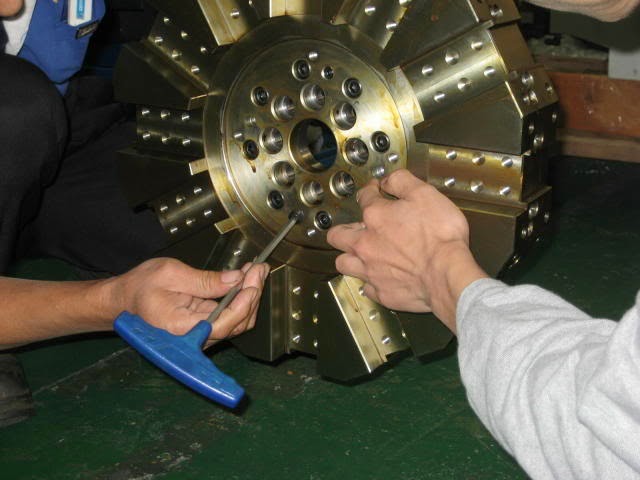

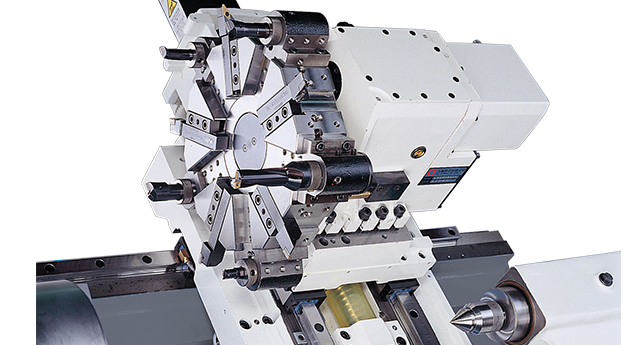

The CORRECT Way to Load Your Tool Turret

Did you know there is a right way and wrong way to load up your CNC lathe's tool turret? Discover tips, tricks and the why's in this article.

MOVE THAT VISE !!

Do you always place your vise or fixture in the middle of the table? If your answer is YES ... you could be KILLING your mill. Find out why in this important article and keep your CNC mill running strong.

Chip Removal ... AIR vs. WATER

Using that air hose to remove chips could just be KILLING your CNC machine. Learn why in this important article on machine maintenance.

Fanuc MACRO Programming Training Series

Always wanted to learn FANUC MACRO programming? Our BLOG has an 8 part training series ... all free ... with in-depth explanations and video tutorials This series is taken from our many years of teaching macro in shops around the country. ENJOY !!

When is a G code program MORE THAN a G code program?

When it's a Set-Up Sheet as well. Explore types of comments ... importance of comments ... and the why's of including comments in your G code programs in this article.

Homemade Barpuller for Your CNC Lathe

One of our most popular posts over the years. This simple design has helped thousands of shops around the world get more efficient and more productive. This article lays out the features, design and sample CNC programming to get you up and running quickly with a complete understanding of one of the most important and efficient processes in CNC turning.

Explore The REAL WORLD of Machining

Explore important TIPS and TRICKS for all things metalworking, machining and CNC gathered over our 35+ years in metalworking. Experiences that include machining from manual machinist to CNC, CNC maintenance and service engineering for some of the top CNC manufacturers like DMG-MORI, years of CNC programming in everything from job shops to high production facilities. We share these varied experiences with the worldwide community in our CNC MACHINIST BLOG. REAL WORLD content to share with the REAL WORLD.

In addition … we have created a line of CNC programming, estimating and pioneering G code conversion software through our KIPWARE® line of CNC / Machine Shop Software. Kipware® is one of the fastest growing brands in machine shops around the world. Interested? Check ’em out through the link below.

Kipware® - Real World Machine Shop / CNC Software

Some of our other popular blog posts that might interest you ...

We are always creating new content based on our 35+ years of machining, machine shop management and machine shop software development experiences.

We invite you to stop by often and check for new content. We are sure that you will find many TIPS and TRICKS for machine maintenance … CNC programming … and machine shop management.